It’s difficult to describe the experience at Hannover Messe. It’s akin to the experience of a child (aka me) in a (technology) sweet shop. So many amazing exhibits, great technologies and fascinating discussions. Dilemas, dilemas; what to look at, what to look at next.

Dare I suggest that what to many visitors might have be seen as exceptional (tech,possibilities etc.), now risks appearing as ‘the norm’. I suspect many of those visiting have their expectations raised by just being here.

The feeling I have from talking to many, many IT exhibitors is that it’s much clearer mow as to how to justify new (especially Cloud and IIoT/IoT) technologies, how one might integrate, and how to get going.

One thing I have noticed is that the (especially digital) exhibits here, reflects how companies such as Microsoft, and others, have become much more switched on to the industrial focus that’s needed to empathise and connect with their target (digital, manufacturing) customers. I suggest that one of the most tangible results of this transformation will be more productive and rapid business outcomes for their customers. Here’s hoping!

On to day 4….. Diego and I spent time looking at the state of robotic art in hall 17, and what’s next, research and futuristic exhibits in hall 2.

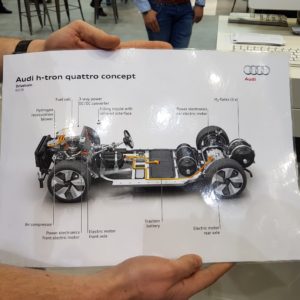

We (Diego) spoke to Marvin Raaijmakers from Audi on the future technologies embedded in the Audi h-tron concept car.

Next we stopped off at one of the (many) university stands. In this case the Technical University of Munich. Their eCARus program is an novel platform that dovetails research and education into one project stream.

Next on to the impressive Fraunhofer stand withh Greg Rauhoft. Fraunhofer is Europe’s largest application-oriented research organization. This organisation is akin to Manufacturing USA for those that know it. Here we looked at an example of 3D to Simulation Model to Production to IoT….A good example of a production Digital Twin….

Also at the Fraunhofer, Marcus Bocksch demonstrated next-gen augmented technologies for manufacturers, employing a smart drill (sensor), location services and manufacturing build/service instructions.

Some rather nice robotics technologies at the DLR stand, employing smart glove and smart clothing, a simulated model (leveraging Matlab/Simulink) and corresponding sensor driven robotics.

Our next stop was to hall 17, Robotics. Some great eye-candy…

….and a chance to catch-up with the latest in robotics, cobots (collaborative robots) and with innovators such as rethink robotics. Darius Wilke explains their product demonstration.

And Diego tries to break it…